condix

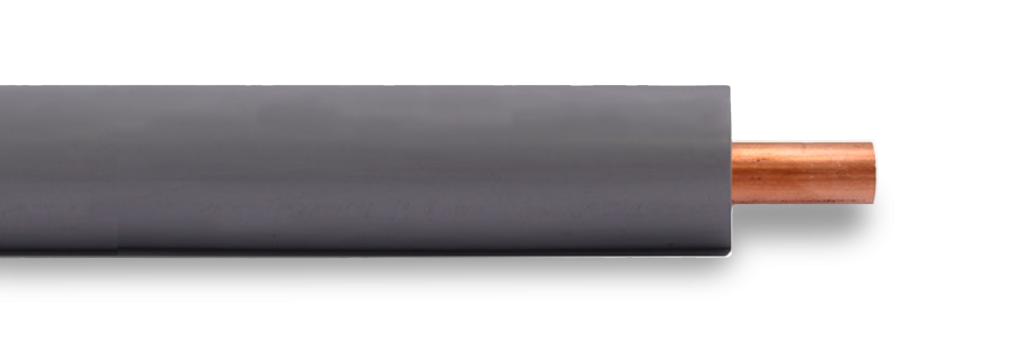

PRE-INSULATED COPPER PIPE WITH SEAMLESS ANTI-CONDENSATION SHEATH IN PE FOAM. EUROCLASS BL S1 D0.

Insulating material in seamless extruded PE foam, with closed cells and a very high resistance factor to the diffusion of water vapour. The Condix series has the best fire resistance thanks to the exclusive processing of the insulating sheath and outer film (Euroclass BL s1 d0)

- Thermal conductivity at 40°C λ ≤ 0,040 W/m*K

- Water vapour diffusion resistance factor (anti-condensation) ≥ 15000 μ

- Fire reaction Euroclass BL s1 d0 (EN13501:2019)

- Operating temperature -40° ÷ +100°C

- Does not contain CFCs

The insulating sheath is not cut or welded to ensure maximum integrity of the product. Smooth external film in pearl grey LDPE with high mechanical resistance.

ACR Copper Cu-DHP 99.90 min. annealed (R220) seamless for refrigerant gases.

- Mechanical properties, dimensions, tolerances, and eccentricity in compliance with the EN 12735-1 standard.

- Specific for all air conditioning, refrigeration and heat

pump systems that use refrigerant gases such as A1, A2L and A3. - Internal cleanliness is ensured by sealing the ends of each tube.

- Carbon residue <0,34 mg/dm².

- Sealed ends as per ASTM B280.

Specific for all air conditioning, refrigeration and heat

pump systems that use refrigerant gases such as A1, A2L and A3.

| Copper pipe diameter | Copper pipe thickness | Nominal thk insulating sheath | Nominal external diameter | Max operating pressure** | ||||

|---|---|---|---|---|---|---|---|---|

| Inch (mm) | mm | mm | mm | MPa | ||||

| 1/4” (6,35) | 0,8 | 6 | 9* | 13* | 18 | 24 | 32 | 13 |

| 3/8” (9,52) | 0,8 | 6 | 9* | 13* | 22 | 28 | 36 | 8,7 |

| 1/2” (12,70) | 0,8 | 6 | 9* | 13* | 25 | 31 | 39 | 7 |

| 1/4” (6,35) | 1 | 6 | 9* | 13* | 18 | 24 | 32 | 15 |

| 3/8” (9,52) | 1 | 6 | 9* | 13* | 22 | 28 | 36 | 10 |

| 1/2” (12,70) | 1 | 6 | 9* | 13* | 25 | 31 | 39 | 8 |

| 5/8” (15,87) | 1 | – | 9 | 13* | – | 34 | 42 | 6,3 |

| 3/4” (19,05) | 1 | – | 9 | 13* | – | 37 | 45 | 5,8 |

| 7/8” (22,22) | 1 | – | 9 | 13* | – | 40 | 48 | 5 |

1 Megapascal = 10 bar – *ref ASTM B 111

other products in the sector

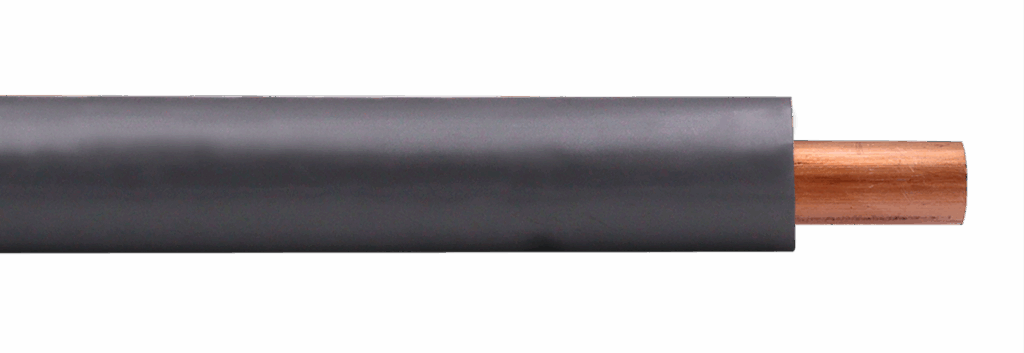

PRE-INSULATED COPPER TUBE WITH ANTI-CONDENSATION SHEATH IN EXPANDED CROSS-LINKED PE FOAM

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 22,22 mm

Euroclass

Euroclass BL s2 d0

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 22, 22 mm

Euroclass

Euroclass BL s1 d0.

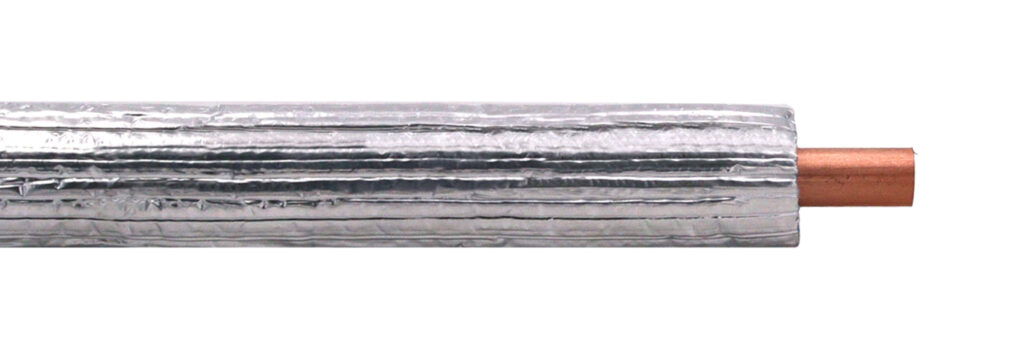

Fields of use

Designed specifically for critical geographic areas or areas with high solar radiation, it adapts to all air conditioning, refrigeration and heat pump systems that use class A1, A2L e A3 gases.

Tube Diameter

Ø 6,35 – 15,87 mm

Euroclass

Euroclass BL s1 d0.

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 22,22 mm

Euroclass

Euroclass BL s2 d0

Fields of use

Specific for air conditioning, refrigeration, heat pumps, and industrial applications.

Tube Diameter

Ø 5 – 28 mm

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 22,22 mm

Euroclass

Euroclass BL s2 d0

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 15,87 mm

Euroclass

Euroclass BL s1 d0

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 15,87 mm

Euroclass

Euroclass BL s2 d0

Fields of use

Specific for air conditioning, refrigeration, heat pumps, and industrial applications.

Tube Diameter

Ø 5 – 28 mm

Fields of use

For all systems that use refrigerant gases such as A1, A2L, and A3.

Tube Diameter

Ø 6,35 – 22,22 mm

Euroclass

Euroclass BL s2 d0

Fields of use

Air conditioning, refrigeration, heat pumps.

Tube Diameter

Ø 6,35 – 22,22 mm

Euroclass

Euroclass BL s1 d0